| |

| Examples of Current and Prior Projects |

| Capabilities by Category |

| Prior Business Collaborations |

| About Us |

| Site Map |

| Contact Us |

| Home |

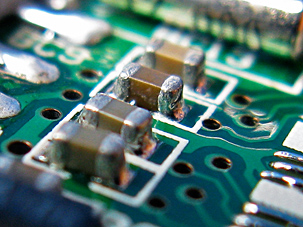

Example 3: Implementation of a ceramic

thin-film capacitor deposition production

process for a large semiconductor company. |

|

|

|

||