| |

| Examples of Current and Prior Projects |

| Capabilities by Category |

| Prior Business Collaborations |

| About Us |

| Site Map |

| Contact Us |

| Home |

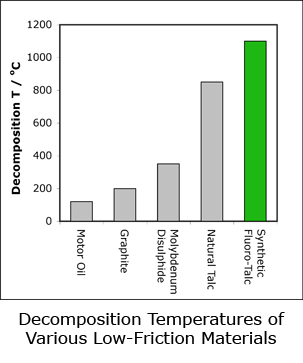

Example 4: Under sub-contract to

Corning Inc., the development of a new ceramic material for aerospace applications. |

|

|

|

||

RESULTS:

RESULTS: